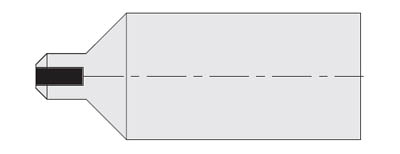

The single point dresser is made of synthetic diamond (CVD or MCD) or a natural diamond, preferably an octahedron. The hard material is gripped in a mount that is suitable for the machine toolholder and direction of use. Diamonds of many different grades and dimensions are used depending on the customer’s requests and the application. The main applications for these dressers are small single-profile grinding wheels and internal cylindrical grinding. An exception to this is the profile diamond with a pre-ground radius and angle, which is also used for larger grinding wheels and wheels with complex profiles. Cars is required when using these individual dressing tools, as the exposed hard diamond tips are susceptible to vibration and impacts as well as large variations in temperature, which can cause damage to the tool.

Single point dressers with MCD needles

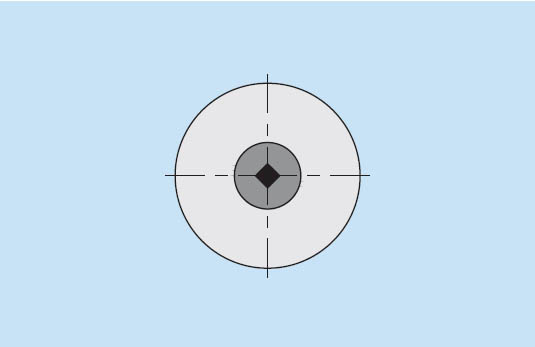

This single point dresser consists of a synthetic MCD needle gripped in a holder. The advantage of the synthetic diamond over the natural one is that its precise geometry remains constant over the whole of its working life. This guarantees an uniformly high surface finish that can be reproduced every time without the need to change any set variables such as feed. It is therefore highly suitable for CNC dressing processes and the machining of small grinding wheels, including profiled ones, and internal cylindrical grinding. There is a cutout in the head of the dresser to make it easier to position the needle correctly with respect to the grinding wheel when setting up The MCD needle is sintered in diagonally with respect to the cutout as this guarantees the longest possible tool life. The cutout must therefore be at right angles to the grinding wheel to obtain the maximum benefit.

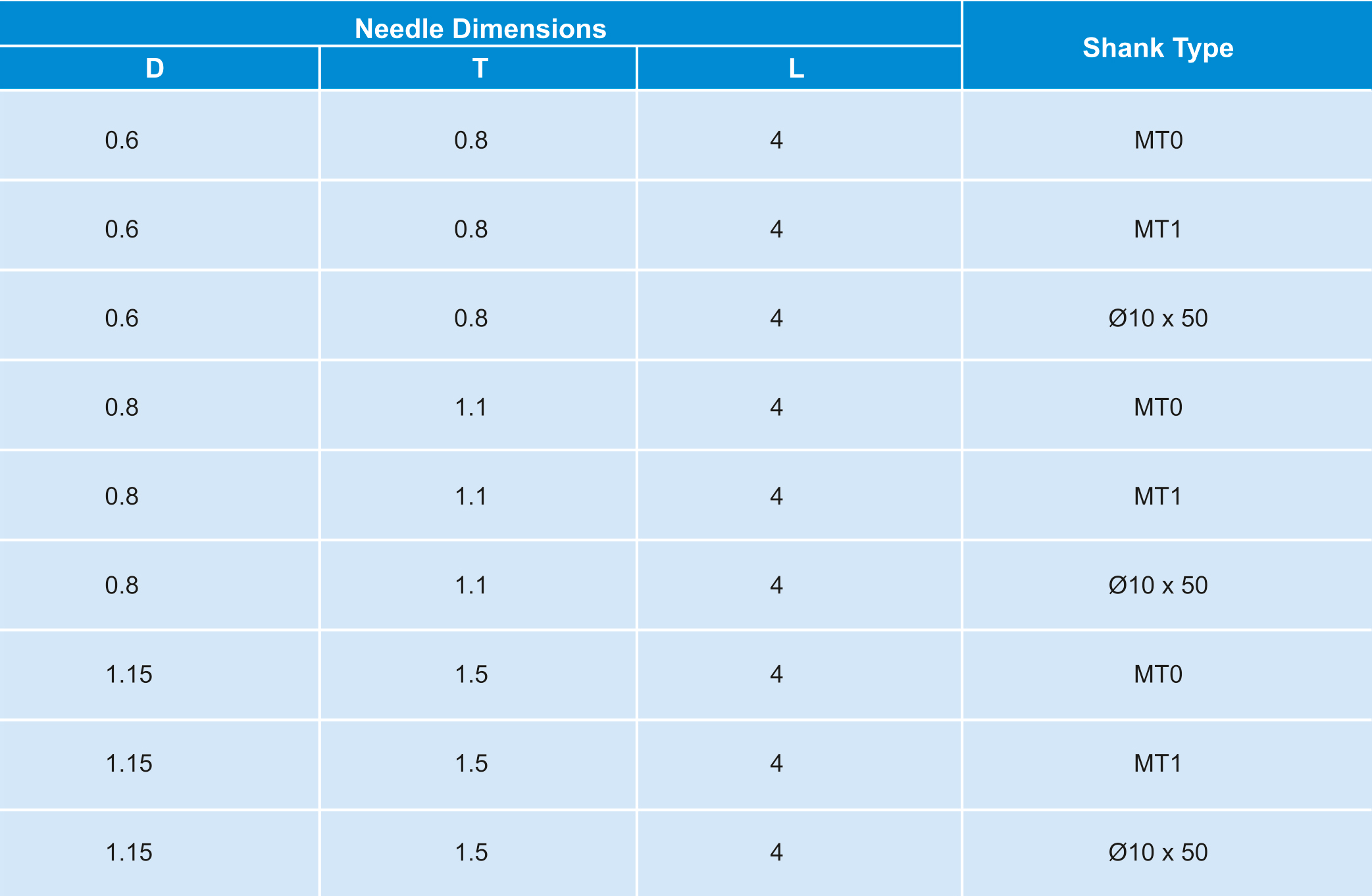

Standard range of single point dressers with MCD needles

Other Shank dimensions available on request.

All dimensions in mm