Single point dressers with CVD needles

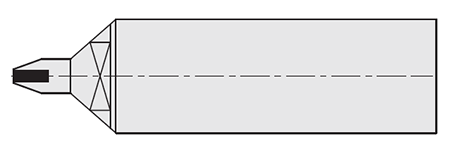

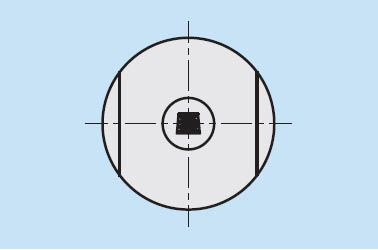

This single point dresser consists of a synthetic CVD needle gripped in a holder. The advantage of the synthetic diamond over the natural one is that its precise geometry is retained over the whole of its working life. This guarantees an uniformly high surface finish that can be reproduced every time without the need to change any process variables such as feed. It is therefore highly suitable for CNC dressing processes and the machining of small grinding wheels, including profiled ones, and internal cylindrical grinding. There is a cutout in the head of the dresser to make it easier to position the needle correctly with respect to the grinding wheel when setting up. Since this is a CVD needle, its orientation to the grinding wheel has no significant effect on the tool life of the dresser. Nevertheless it should be noted that the diagonal mounting leads to a greater overlap IT dimension). The CVD is sintered into the shank horizontally with respect to the cutout and in this position the T dimension is the smallest.

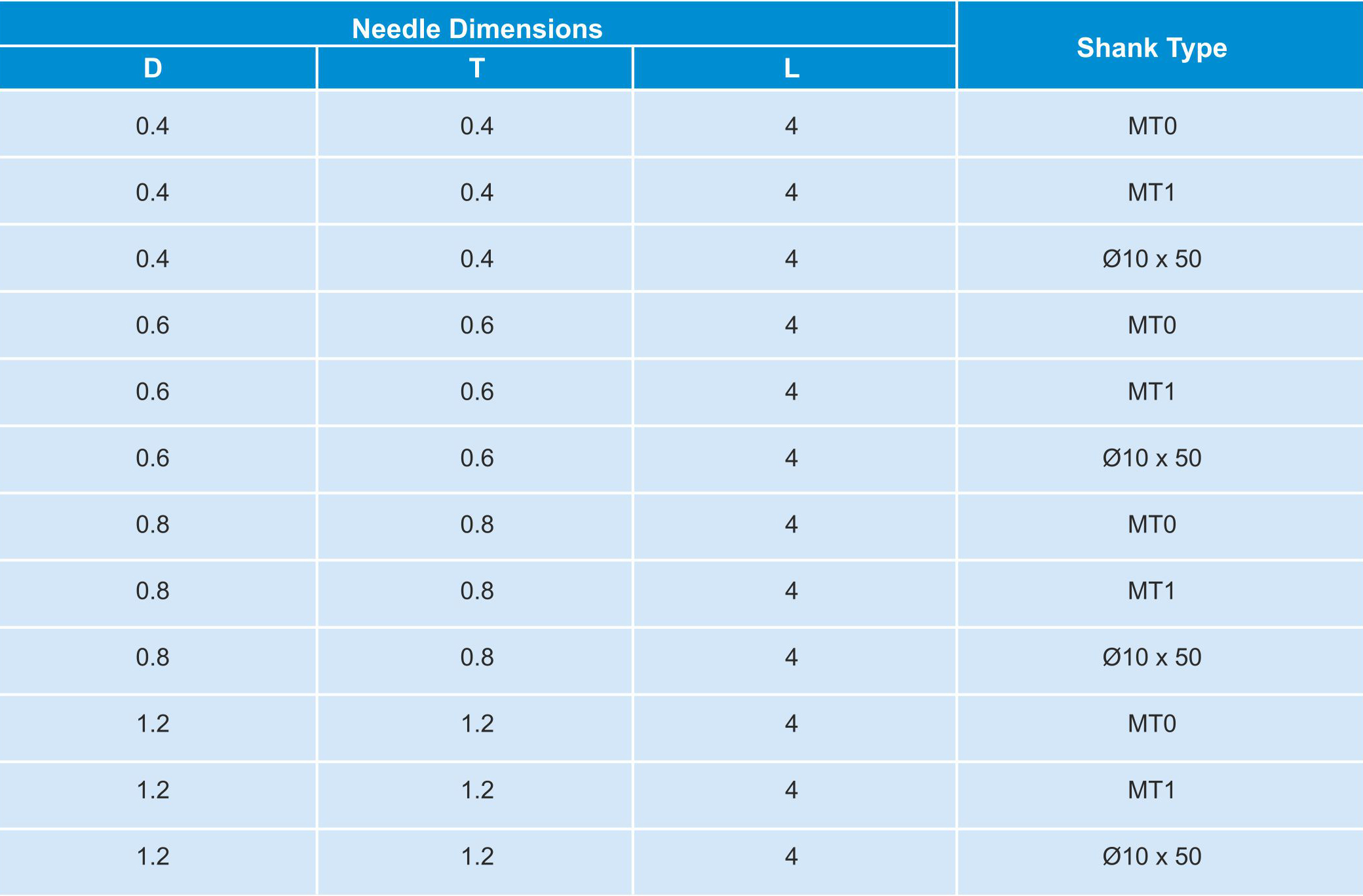

Standard range of single point dressers with CVD needles

Other Shank dimensions available on request.

All dimensions in mm