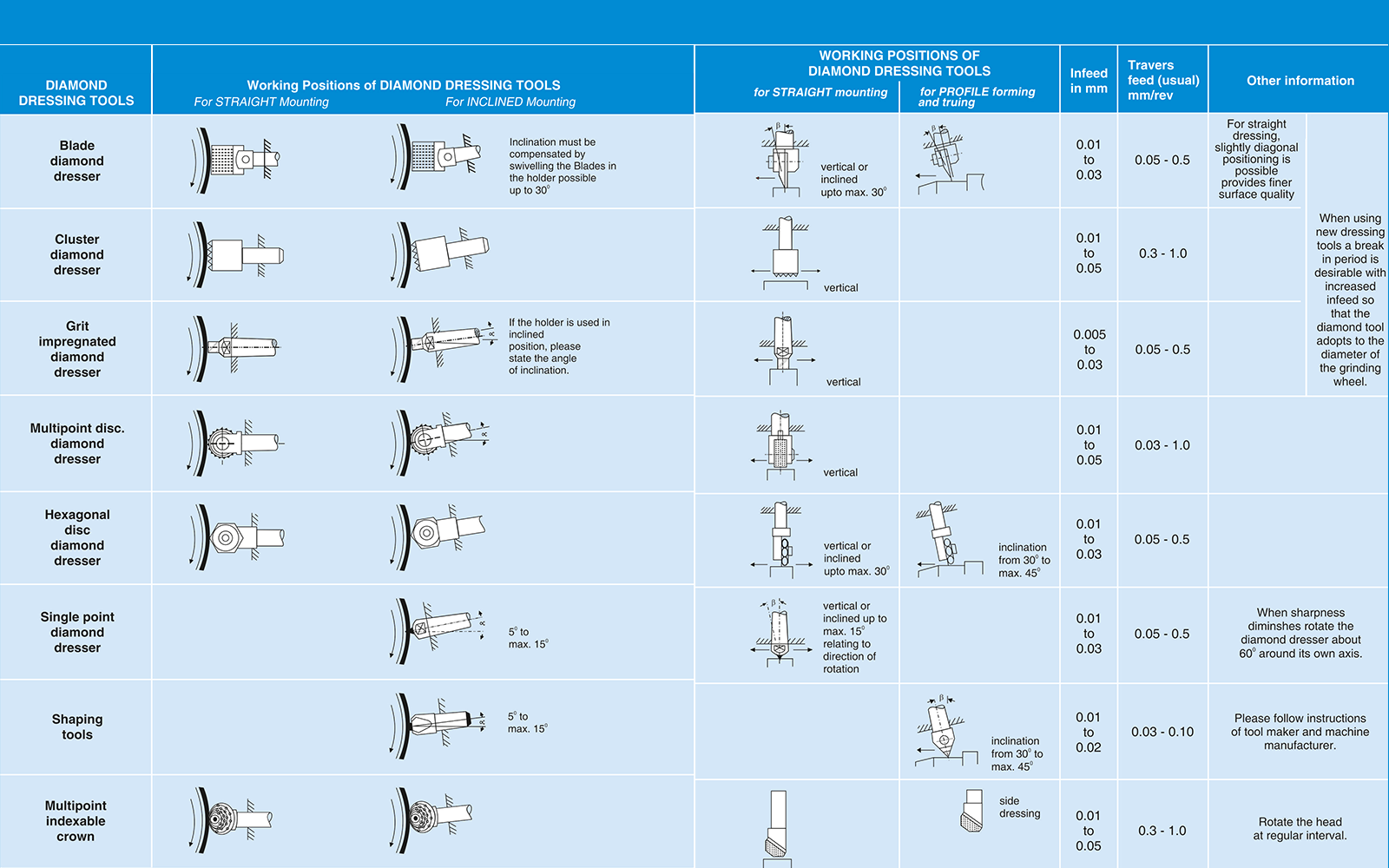

Wheel speed for dressing and truing : Normal grinding speed.

Copious and uninterrupted coolant supply is recommended. This increases the life of the diamond dressing tool and is often essential for proper functioning cooling tool engages the wheel.

To change the effective roughness of the wheel normally it is best to change transverse feed. Increasing infeed rate has less effect and shortens dressing tool life.

Tool mounting must be vibration-free, with the clamping length as short as possible.